Submersible Nozzles

Submersible Nozzles

Submersible nozzles of corundum-graphite composition are manufactured by new technologies providing thermal shock and wear resistance of the product.

Depending on service conditions and design and process features of customer's equipment JSC “Borovichi Refractories Plant” has possibility to produce submersible

nozzles of various configuration (direct-flow, closed-bottomed with different number of and direction of outflow openings) and differentiated by chemical and substance

composition (slag belt, anticlogging coating of internal channel).

All submersible nozzles are subject to nondestructive testing at X-ray apparatus Artikon-305 for the purpose of hidden defects detection (internal cracks, flaws, foreign

inclusions, etc.).

External surface of submersible nozzles is covered with high quality porcelain enamel providing complete protection of graphite against burning-out during nozzles

heating-up.

Design of submersible nozzles assumes taper or spherical joining with nonswirl nozzle using felt gasket on account of hollow space equaled to 3 mm between contact

surfaces of submersible nozzle and nonswirl nozzle. In accordance with the customer's option argon flow to the point of submersible nozzle and nonswirl nozzle connection

is allowed.

Prior to application submersible nozzles shall be preheated up to the temperature of 800°С. In order to prevent burning-out of graphite, submersible nozzles in heated

state (at 800°С) are recommended to be held not more than three hours.

It is possible to manufacture submersible nozzles with argon flow to the point of submersible nozzle and nonswirl nozzle connection both by customer’s drawings and

manufacturer’s designs.

Technical characteristics

| Rate for grade | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PS-KGC | PS-KGCA | PS-KGCD | PS-KGCAD | |||||||||

| КG | C |

КG | C | А | КG | C | D | КG | C | А | D | |

| Spec. 14-194-274-06 rev.1-3 | ||||||||||||

|

Mass fraction of dry substance, %: Al2O3, minimum С, minimum ZrO2, minimum |

25 - |

15 68 |

25 - |

15 68 |

18 - |

25 - |

15 68 |

22 - |

25 - |

15 68 |

18 - |

25 - |

| Apparent density, g/cm³, minimum | 2,40 | 3,45 | 2,40 | 3,45 | - | 2,40 | 3,45 | 2,50 | 2,40 | 3,45 | - | 2,50 |

| Open porosity, % maximum | 17 | 18 | 17 | 18 | - | 17 | 18 | 16 | 17 | 18 | - | 16 |

| Rate for grade | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| materials of cylindrical part the submersible nozzle | material of upper layer of funnel | material of slag belt | material of antikleking layer | materials of bottom part (chopper) | |||||||

| PS | PS1 |

PS2 | V | C1 | C2 | C3 | C4 | А | D | D1 | |

| Spec. 14-194-286-09 rev.1 | |||||||||||

|

Mass fraction of dry substance, %: Al2O3, minimum С, minimum ZrO2, minimum SiO2, maximum |

54 24 - - |

55 20 - - |

63 15 - - |

53 9 - - |

- 10 73 - |

- 10 70 - |

- 8 74 - |

- 10 72 - |

55 maximum20 - 40 |

58 22 - - |

63 15 - - |

| Apparent density, g/cm³, minimum | 2,40 | 2,42 | 2,55 | 2,40 | 3,65 | 3,60 | 3,68 | 3,63 | - | 2,50 | 2,55 |

| Open porosity, % maximum | 17 | 17 | 20 | 20 | 17 | 17 | 17 | 17 | - | 16 | 20 |

| Rate for grades | |||

|---|---|---|---|

| КUPS-65 | КUPS-CZS | ||

| Nozzle | Protective layer | ||

| GOST R 52801-2007 | |||

|

Mass fraction of dry substance, %: Al2O3, minimum С, minimum ZrO2, minimum |

65 24 - |

63 19 - |

- 10 70 |

| Open porosity, % maximum | 16 | 20 | 23 |

Limit deviations of dimensions, mm

| Dimensions, mm | Limit deviations dimensions Spec.14-194-274-06 rev.1-3, Spec.14-194-286-09 rev.1, mm |

|---|---|

| Diameter: | |

| outside | ±5 |

| inside | ±1 |

| Height: | |

| up to 750 inc. | ±10 |

| over 750 | ±20 |

| Dimensions, mm | Limit deviations | |

|---|---|---|

| КUPS-65, КUPS-CZS | ||

| unglazed | glazed | |

| Diameter: | ||

| up to 50 inc. | ±2 | ±3 |

| over 50 up to 100 inc. | ±3 (±4) | ±4 (±5) |

| over 100 | ±6 | ±7 |

| Height: | ||

| up to 750 inc. | ±10 | ±11 |

| Height of bead and groove | ±5 | ±6 |

| Angle 25° | ±5° | ±6° |

Dimensions of submersible nozzles GOST R 52801-2007

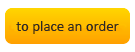

| Number | H | h | h1 | h2 | d | d1 | d2 | A | B | a | b |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 23 | 500 | 41 | 60 | 80 | 60 | 132 | 70 | 165 | 160 | 120 | 115 |

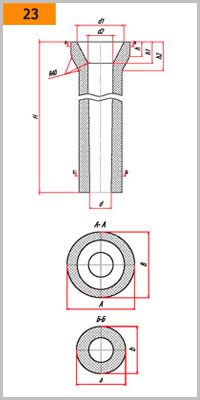

| Number | H | h1 | h2 | D | D1 | D2 | d | d1 | d2 | d3 |

|---|---|---|---|---|---|---|---|---|---|---|

| 24 | 570 | 24 | 52 | 120 | 50 | 66 | 30 | 95 | 82 | 46 |

| Number | H | h | h1 | h2 | h3 | h4 | D | D1 | D2 | d | d1 | d2 | d3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 25 | 680 | 70 | 60 | 50 | 35 | 75 | 185 | 170 | 150 | 75 | 155 | 95 | 75 |

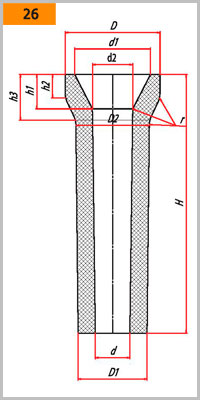

| Number | H | h | h1 | h2 | D | D1 | D2 | d | d1 | d2 | r |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 26 | 700 | 60 | 41 | 80 | 165 | 120 | 128 | 60 | 132 | 70 | 40 |