Refractories for steel ladle lining

Refractories are used for steel ladle lining and other termal units.

Technical characteristics

| Rate for grade | |||||

|---|---|---|---|---|---|

| ShKU-32 | ShKU-37 | MKRKU-45 |

MKRKP-45 |

MLKS-62 | |

| GOST 5341-2016 |

|||||

|

Mass fraction, %: Al2O3, minimum Al2O3, over Fe2O3, maximum |

32 - - |

37 - - |

- 45 3,5 |

- 45 3,5 |

- 62 1,4 |

| Refractoriness, °С, minimum | 1690 | 1730(1710) | 1730 | 1730 | - |

| Compressive strength, N/mm2, minimum | 27 | 30(27) | 35 | 40 | 30 |

| Open porosity, %, maximum | 19 | 18(19) | 18 | 16 | 22 |

|

Residual variations of sizes when heating, %, maximum at: 1400 °C 1500 °C |

+0,3 - |

+0,3 - |

+0,4 - |

+0,2 - |

- 0,4 |

| Temperature of initial softening, °С, minimum | 1370 | 1400(1370) | 1400 | 1400 | 1450 |

| Thermal shock resistance, heat cycles , minimum |

4* | 4(3)* | 3* | 4* | - |

| Rate for grade | |||||

|---|---|---|---|---|---|

| MLKU-62 |

MLKU-69 | MKKS-72 | MKKS-75 | MKKS-90 | |

| GOST 5341-2016 |

|||||

|

Mass fraction, %: Al2O3, minimum Al2O3, over Fe2O3, maximum |

- 62 1,1 |

69 - 1,0 |

- 72 1,5 |

75 - 2,2 |

90 - 0,8 |

| Compressive strength, N/mm2, minimum | 50 | 50 | 30 | 40 | 50 |

| Open porosity, %, maximum | 17 | 19 | 24 | 23 | 24 |

|

Residual variations of sizes when heating, %, maximum at: 1600 °C |

- |

- |

+1,0 |

+2,5 |

- |

| Temperature of initial softening, °С, minimum | 1600 | 1650 | 1500 | 1420 | 1660 |

| Thermal shock resistance, heat cycles , minimum |

15* | 15* | - | 3* | - |

*Rates are defined as agreed between the consumer and manufacturer.

| Rate for grade | |||

|---|---|---|---|

| KMKRU-45 | KMKRU-50 | KMKRU-55 | |

| Spec. 14-8-647-94 rev. 1-3 | |||

|

Mass fraction, %: Al2O3, minimum Fe2O3, maximum |

45 3,5 |

50 4,4 |

55 4,0 |

| Refractoriness, °С, minimum | 1730 | 1730 | 1730 |

| Compressive strength, N/mm2, minimum | 35 | 33 | 35 |

| Open porosity, %, maximum | 19 | 19 | 19 |

|

Residual variations of sizes when heating, %, maximum at: 1400 °C |

0,4 |

0,4 |

0,4 |

| Thermal shock resistance, heat cycles , minimum |

4 | 4 | 4 |

| Rate for grade | ||

|---|---|---|

| KBU | KBU-60 | |

| Spec. 14-194-300-10 rev. 1 | ||

|

Mass fraction, %: Al2O3, minimum Fe2O3, maximum |

55 4 |

60 3 |

| Refractoriness, °С, minimum | 1750 | 1770 |

| Compressive strength, N/mm2, minimum | 35 | 45 |

| Open porosity, %, maximum | 20 | 19 |

|

Residual variations of sizes when heating, %,within limits of: 1400 °C |

from -0,4 to +1,0 |

from -0,4 to +1,0 |

| Thermal shock resistance, heat cycles , minimum |

4 | 6 |

Form and dimensions

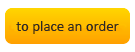

Double-sided featheredge brick

| Number of brick | Dimensions, mm | Group of complication | |||

|---|---|---|---|---|---|

| S | S1 | L | H - course thickness | ||

| 1 | 140 | 120 | 250 | 65 | 3 |

| 2 | 140 | 125 | 250 | 80 | 4 |

| 2а | 80 | 68 | 300 | 120 | 4 |

| 2б | 80 | 68 | 300 | 160 | 4 |

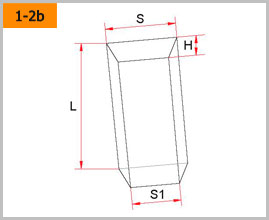

End arch brick

| Number of brick | Dimensions, mm | Group of complication | |||

|---|---|---|---|---|---|

| S | S1 | L | H- course thickness |

||

| 3 | 140 | 135 | 250 | 65 | 3 |

| 4 | 140 | 135 | 250 | 80 | 4 |

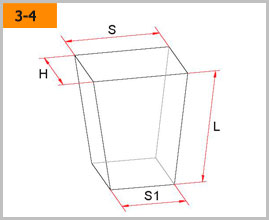

Trapezoidal brick

| Number of brick | Dimensions, mm | Group of complication | |||

|---|---|---|---|---|---|

| S | S1 | L | H-course thickness |

||

| 6 | 250 | 239 | 80 | 80 | 4 |

| 7 | 210 | 181 | 80 | 100 | 4 |

| 8 | 230 | 209 | 80 | 100 | 4 |

| 9 | 250 | 236 | 80 | 100 | 4 |

| 10 | 210 | 176 | 80 | 120 | 4 |

| 11 | 230 | 206 | 80 | 120 | 4 |

| 12 | 230 | 212 | 80 | 120 | 4 |

| 13 | 250 | 235 | 80 | 120 | 4 |

| 14 | 210 | 178 | 80 | 150 | 4 |

| 14а | 225 | 205 | 80 | 150 | 4 |

| 15 | 230 | 205 | 80 | 150 | 4 |

| 15а | 245 | 210 | 80 | 150 | 4 |

| 16 | 250 | 232 | 80 | 150 | 4 |

| 16а | 250 | 228 | 80 | 150 | 4 |

| 18 | 220 | 192 | 80 | 200 | 4 |

| 19 | 240 | 216 | 80 | 200 | 4 |

| 20 | 230 | 200 | 80 | 250 | 4 |

| 21 | 250 | 221 | 80 | 250 | 4 |

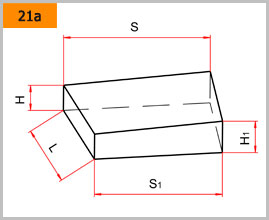

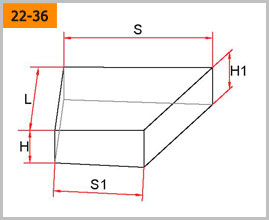

Trapezoidal brick b/b1<1

| Number of brick | Dimensions, mm | Group of complication | ||||

|---|---|---|---|---|---|---|

| S | S1 | L | H1 | H-course thickness |

||

| b/b1 ≥1 | ||||||

| 21a | 240 | 213 | 200 | 80 | 60 | 4 |

| Number of brick | Dimensions, mm | Group of complication | ||||

|---|---|---|---|---|---|---|

| S | S1 | H | H1 | L-course thickness |

||

| b/b1 ≤1 | ||||||

| 22 | 230 | 205 | 40 | 40 | 150 | 4 |

| 23 | 230 | 205 | 40 | 50 | 150 | 4 |

| 24 | 230 | 205 | 50 | 60 | 150 | 3 |

| 25 | 230 | 205 | 60 | 70 | 150 | 4 |

| 26 | 230 | 205 | 70 | 80 | 150 | 4 |

| 27 | 220 | 192 | 40 | 40 | 200 | 4 |

| 28 | 220 | 192 | 40 | 50 | 200 | 4 |

| 29 | 220 | 192 | 50 | 60 | 200 | 3 |

| 30 | 220 | 192 | 60 | 70 | 200 | 4 |

| 31 | 220 | 192 | 70 | 80 | 200 | 5 |

| 32 | 250 | 221 | 40 | 40 | 250 | 5 |

| 33 | 250 | 221 | 40 | 50 | 250 | 4 |

| 34 | 250 | 221 | 50 | 60 | 250 | 4 |

| 35 | 250 | 221 | 60 | 70 | 250 | 4 |

| 36 | 250 | 221 | 70 | 80 | 250 | 5 |

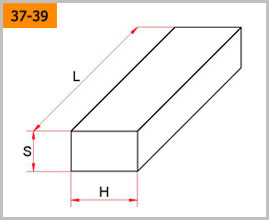

Straight brick

| Number of brick | Dimensions, mm | Group of complication | ||

|---|---|---|---|---|

| L | S | H |

||

| 37 | 250 | 80 | 100 | 3 |

| 38 | 300 | 80 | 120 | 3 |

| 39 | 300 | 80 | 150 | 3 |

| Dimensions | Limit deviations, maximum for class |

|---|---|

| MKRKU-45, MKRKP-45, MLKS-62, MLKU-62, MLKU-69, MKKS-72, MKKS-75, MKKS-90 | |

| Up to 100 mm inc. | ±1 |

| Over 100 to 300 mm inc. | ±2 |

| over 300 mm | ±3 |

| Number of brick | Dimensions, mm | Limit deviations |

|---|---|---|

| KMKRU-45, KMKRU-50, KMKRU-55, ShKU, ShKU-32, MKRKU-45 | ||

| 1-4 | а and а1 | ±3 |

| с | +2 | |

| -1 | ||

| d | ±2 | |

| 2a, 2b | a and a1 | +2; -1 |

| c | ±3 | |

| d | ±2 | |

| 6-36 | a, a1 and с | ±3 |

| b and b1 | +2 | |

| -1 | ||

| 37-39 | а and с | +3 |

| -2 | ||

| b | +2 | |

| -1 | ||