Refractories for open-hearth checkers

Refractories are intended for lining of open-hearth checkers and other thermal units.

Technical characteristics

| Rate for grade | ||

|---|---|---|

| ShN-38 | ShN-45 | |

| Spec. 1546-002-00190495-97 rev.1 | Spec. 14-194-262-03 | |

|

Mass fraction, %: Al2O3, minimum Fe2O3, maximum |

38 - |

45 3,5 |

| Compressive strength, N/mm2, minimum | 22 | 35 |

| Open porosity, %, maximum | 21 | 20 |

| Residual variation of dimensions when heating, %, maximum at 1400 °С | 0,4 | 0,4 |

| Refractoriness, °С, minimum | 1730 | 1750 |

| Thermal shock resistance, heat cycles, minimum | - | 3 |

| Temperature of initial deformation under load, °С, minimum | 1400 | 1400 |

Limit deviations of refractory dimensions (mm)

| Types and dimensions of items | Limit deviations | |

|---|---|---|

| ShN-38 | ShN-45 | |

| Items of rectangular form: | ||

| length | ±3 | ±4 |

| width | ±2 | ±2 |

| heigth | ±2 |

±2 |

| Shaped items: | ||

| up to 100 mm inc. | ±2 |

±2 |

| over 100 up to 400 mm inc., % | ±1,5 | ±1,5 |

Form and dimensions

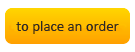

Straight brick GOST 8691-73 rev.1-4

| Number of bricks | Dimensions, mm | Group of complication | ||

|---|---|---|---|---|

| a | b | c | ||

| 2 | 230 | 65 | 85 | 3 |

| 5 | 230 | 65 | 114 | 1 |

| 8 | 250 | 65 | 124 | 1 |

| 9 | 300 | 65 | 150 | 2 |

| 10 | 345 | 75 | 150 | 3 |

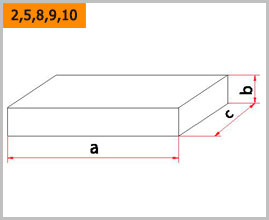

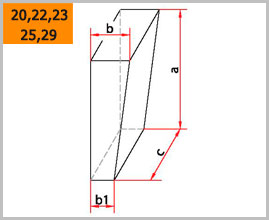

End arch brick (one sided and double-sided) GOST 8691-73 rev.1-4

| Number of bricks | Dimensions, mm | Group of complication | |||

|---|---|---|---|---|---|

| a | b | b1 | c | ||

| 20 | 230 | 75 | 65 | 114 | 4 |

| 22 | 230 | 65 | 55 | 114 | 3 |

| 23 | 230 | 65 | 45 | 114 | 4 |

| 25 | 250 | 65 | 55 | 124 | 3 |

| 29 | 300 | 65 | 55 | 150 | 4 |

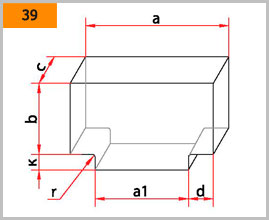

T-type checker and unchecker brick GOST 6024-75 rev.1-3

| Number of brick | Dimensions, mm | ||||||

|---|---|---|---|---|---|---|---|

| a | a1 | b | с | d | k | r | |

| 39 | 230 | 150 | 114 | 75 | 40 | 25 | 5 |