Periclase-spinel Refractories

Periclase-spinel refractories are used for lining of rotary kilns used in cement industry.

Technical characteristics

| Rate for grade | ||

|---|---|---|

| PShAC | PShAC-20 | |

| Spec. 14-194-249-01 rev.1 |

||

|

Mass fraction for baked substance, %: MgO, minimum Al2O3, withing limits of CaO, maximum SiO2, maximum ZrO2, withing limits of Fe2O3, maximum |

85 4-8 1,5 1,0 1-3 1,0 |

87 6-10 2,0 1,0 n/a 1,0 |

| Compressive strength, N/mm2, minimum | 40 | 50 |

| Open porosity, %, maximum | 17 | |

| Residual variation of dimensions when heating at 1650 °С, %, maximum | 0,7 | |

| Apparent density, g/cm3, minimum | 2,9 | |

| Thermal shock resistance, heat cycles (1300°С - water), minimum | 7 | 15 |

| Temperature of initial sotening under load of 0,2 MPa, °С, minimum | 1690 |

|

| Thermal conductivity, (W/mK), maximum at temperature of 1000°С | 4,5 | |

Thermal conductivity is determined by agreement between the Parties.

Items are made according to customers’ drawings.

Bricks PShAC may be made according to GOST, systems ISO and VDZ

Form and dimensions of bricks PShAC according to GOST 21436-2004 “Refractory and high-refractory bricks for lining of rotary kilns”

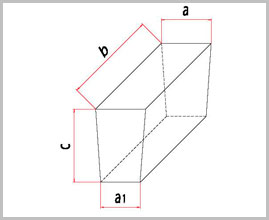

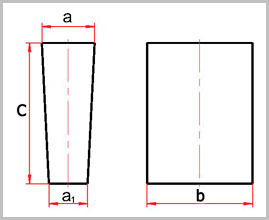

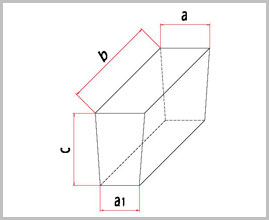

End arch brick (double-sided)

| Number of brick | Dimensions, mm | Application | ||||

|---|---|---|---|---|---|---|

| а | а1 | b | с | In combination with numbers | For furnaces of diameter, m | |

| 21 | 80 | 73 | 200 | 230 |

23, 22, 34 |

3,1-5,4 5,4-7 |

| 22 | 120 | 113 | 200 | 230 | 21, 32 |

3,1-5,4 5,4-7 |

| 23 | 65 | 55 | 200 | 230 |

21 32 |

3,1-5,4 3,1-4,4 |

|

24 25 26 |

70 70 70 |

62 62 57 |

120 150 120 |

200 200 200 |

26 27 24 |

2,2-3,6 2,2-3,6 2,2-3,6 |

| 27 | 70 | 57 | 150 | 200 | 25 | 2,2-3,6 |

| 28 | 65 | 55 | 150 | 230 | 29, 31 |

3,1-5,4 3,1-4,4 |

| 29 | 80 | 73 | 150 | 230 |

28 30, 33 |

3,1-5,4 5,4-7 |

| 30 | 120 | 113 | 150 | 230 | 29, 31 | 4,4-7 |

| 31 | 103 | 92 | 150 | 230 |

28 30, 33 |

3,1-4,4 4,4-7 |

| 32 | 103 | 92 | 200 | 230 |

22, 34 23 |

4,4-7 3,1-4,4 |

|

33 34 |

103 103 |

97 97 |

150 200 |

230 230 |

29, 31 21, 32 |

5,4-7 5,4-7 |

| 35 | 80 | 75 | 150 | 160 |

36 37 |

3,1-5,2 5,2-7 |

|

36 37 38 39 |

65 120 80 65 |

58 115 73 55 |

150 150 115 115 |

160 160 230 230 |

35 35 39 38 |

3,1-5,2 5,2-7 3,1-5,4 3,1-5,4 |

Form and dimensions of bricks PShAC asper system ISO

| Number of brick | Dimensions, mm | Application | |||

|---|---|---|---|---|---|

| а | а1 | b | с | Diameter, mm | |

| 215 | 103 | 87,5 | 198 | 150 | 2026 |

| 315 | 103 | 92,5 | 198 | 150 | 2991 |

| 415 | 103 | 95 | 198 | 150 | 3936 |

| 515 | 103 | 97 | 198 | 150 | 5235 |

| 615 | 103 | 98 | 198 | 150 | 6282 |

| 216 | 103 | 86 | 198 | 160 | 1971 |

| 316 | 103 | 92 | 198 | 160 | 3046 |

| 416 | 103 | 94,5 | 198 | 160 | 3942 |

| 516 | 103 | 96,5 | 198 | 160 | 5154 |

| 616 | 103 | 97,5 | 198 | 160 | 6092 |

| 318 | 103 | 90,5 | 198 | 180 | 3015 |

| 418 | 103 | 93,5 | 198 | 180 | 3968 |

| 518 | 103 | 95,5 | 198 | 180 | 5026 |

| 618 | 103 | 97 | 198 | 180 | 6282 |

| 220 | 103 | 82 | 198 | 200 | 1994 |

| 320 | 103 | 89 | 198 | 200 | 2991 |

| 420 | 103 | 92,5 | 198 | 200 | 3989 |

| 520 | 103 | 94,7 | 198 | 200 | 5046 |

| 620 | 103 | 96,2 | 198 | 200 | 6159 |

| 720 | 103 | 97 | 198 | 200 | 6980 |

| 820 | 103 | 97,8 | 198 | 200 | 8054 |

| 222 | 103 | 80 | 198 | 220 | 2003 |

| 322 | 103 | 88 | 198 | 220 | 3071 |

| 422 | 103 | 91,5 | 198 | 220 | 4006 |

| 522 | 103 | 94 | 198 | 220 | 5119 |

| 622 | 103 | 95,5 | 198 | 220 | 6142 |

| 722 | 103 | 96,5 | 198 | 220 | 7078 |

| 822 | 103 | 97,3 | 198 | 220 | 8082 |

| 225 | 103 | 77 | 198 | 250 | 2013 |

| 325 | 103 | 86 | 198 | 250 | 3079 |

| 425 | 103 | 90 | 198 | 250 | 4027 |

| 525 | 103 | 92,7 | 198 | 250 | 5083 |

| 625 | 103 | 94,5 | 198 | 250 | 6159 |

| 725 | 103 | 95,5 | 198 | 250 | 6980 |

| 825 | 103 | 96,5 | 198 | 250 | 8054 |

Form and dimensions of bricks PShAC as per system VDZ

| Number of brick | Dimensions, mm | Application | |||

|---|---|---|---|---|---|

| а | а1 | b | с | Diameter, mm | |

| В 216 | 78 | 65 | 198 | 160 | 1957 |

| В 416 | 75 | 68 | 198 | 160 | 3497 |

| В 218 | 78 | 65 | 198 | 180 | 2202 |

| В 318 | 76,5 | 66,5 | 198 | 180 | 2808 |

| В 418 | 75 | 68 | 198 | 180 | 3934 |

| В 518 | 74,5 | 68,5 | 198 | 180 | 4560 |

| В 618 | 74 | 69 | 198 | 180 | 5436 |

| В 220 | 78 | 65 | 198 | 200 | 2446 |

| В 320 | 76,5 | 66,5 | 198 | 200 | 3120 |

| В 420 | 75 | 68 | 198 | 200 | 4271 |

| В 520 | 74,5 | 68,5 | 198 | 200 | 5067 |

| В 620 | 74 | 69 | 198 | 200 | 6040 |

| В 222 | 78 | 65 | 198 | 220 | 2691 |

| В 322 | 76,5 | 66,5 | 198 | 220 | 3432 |

| В 422 | 75 | 68 | 198 | 220 | 4809 |

| В 522 | 74,5 | 68,5 | 198 | 220 | 5573 |

| В 622 | 74 | 69 | 198 | 220 | 6644 |

| В 325 | 78 | 65 | 198 | 250 | 3058 |

| В 425 | 76,5 | 66,5 | 198 | 250 | 3900 |

| В 525 | 75 | 68 | 198 | 250 | 5464 |

| В 625 | 74,5 | 68,5 | 198 | 250 | 6333 |

| В 725 | 74 | 69 | 198 | 250 | 7550 |