Locking refractories for steel ladle casting

Locking refractories are used for steel ladle casting

Technical characteristics

| Rate for grade | ||||||

|---|---|---|---|---|---|---|

| Stoppers | ||||||

| ShST-32 | ShST-35 | MLST-63 | МКSТ-73 | МКSТТ-73 | MKBST-75 | |

| GOST R 53066-2008 | ||||||

|

Mass fraction, %: Al2O3, minimum Fe2O3, maximum |

32 - |

35 - |

63 1,3 |

73 1,1 |

73 1,5 |

75 2,2 |

| Refractoriness, °С, minimum | 1690 | 1710 | - | - | - | - |

|

Open porosity, %, within limits of: - semi-dry pressing - plastic formation |

15-26 19-26 |

16-21 - |

16-20 - |

- |

- |

|

|

Residual variation of dimensions when heating,%, maximum at: 1350 °C 1400 °C |

0,3 - |

- 0,1 |

- 0,1 |

- 0,3 |

- 0,1 |

|

| Thermal shock resistance, heat cycles, minimum | 1 | 2 | 2 | 3 | 2 | |

| Rate for grade | ||

|---|---|---|

| Well block | ||

| ShSG-32 | MLSG-62 | |

| GOST R 53066-2008 | ||

|

Mass fraction, %: Al2O3, minimum Fe2O3, maximum |

32 - |

1,5 |

| Refractoriness, °С, minimum | 1690 | - |

| Open porosity, %, maximum |

23 | 24 |

| Compressive strength, N/mm2, minimum | 15 | 25 |

| Temperature of initial softening, °С, minimum | - | 1450 |

| Residual variations of dimensions when heating at 1500°С, maximum | - | 0,4 |

| Rate for grade | |||

|---|---|---|---|

| Stoppers |

|||

| ShSP-32 | ShSP-34 | MKSP-72 | |

| GOST R 53066-2008 | |||

|

Mass fraction, %: Al2O3, minimum |

32 |

34 |

over 72 |

| Refractoriness, °С, minimum | 1690 | 1710 | - |

|

Open porosity, %, within limits of: - semi-dry pressing - plastic formation |

15-20 18-23 |

15-20 18-22 |

16-21 - |

|

Temperature of initial softening, °С, minimum: - semi-dry pressing - plastic formation |

1320 1350 |

- - |

|

| Thermal shock resistance, heat cycles, minimum | 1 | 3 | 1 |

| Rate for grade | |||

|---|---|---|---|

| Nozzle | |||

| ShSS-32 | ShSS-34 | MLSS-62 | |

| GOST R 53066-2008 | |||

|

Mass fraction, %: Al2O3, minimum Fe2O3, maximum |

32 - |

34 - |

1,5 |

| Refractoriness, °С, minimum | 1690 | 1710 | - |

| Open porosity, %, maximum | 22 | 20 | 24 |

| Temperature of initial softening, °С, minimum | 1350 | - | |

| Dimensions | Limit deviations of bricks dimensions | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Tubes | Stoppers | Nozzles | Inserts | Well block | |||||

| mm | % | mm | % |

mm | % | mm | mm | % | |

| Diameter of brick, mm: | |||||||||

| - semi-dry formation: | |||||||||

| up to 50 inc. | ±1 | - | ±1 | - | ±1 | - | ±1 | - | - |

| over 50 up to 100 inc. | ±2 | - | ±2 | - | ±2 | - | ±1 | - | - |

| over 100 | - | ±2 | - | ±2 | ±2 | - | ±2 | - | |

| - plastic formation: | |||||||||

| up to 50 inc. | ±2 | - | ±1 | - | ±1 | - | ±1 | - | - |

| over 50 up to 100 inc. | ±2 | - | ±2 | - | ±2 | - | ±1 | - | - |

| over 100 | - | ±2 | - | ±2 | - | ±2 | - | - | ±2 |

| Diameter of bead and groove | ±1 | - | ±1 | - | - | - | - | - | - |

| Height of bead (h) | ±1 | - | ±1 | - | - | - | - | - | - |

| Height of groove (h1) | ±1 | - | - | - | ±1 | - | - | ±1 | - |

| Height of well for insert (h) of nozzle numbers 25-30, 33, 34 |

- | - | - | - | ±2 | - | - | - | - |

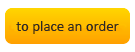

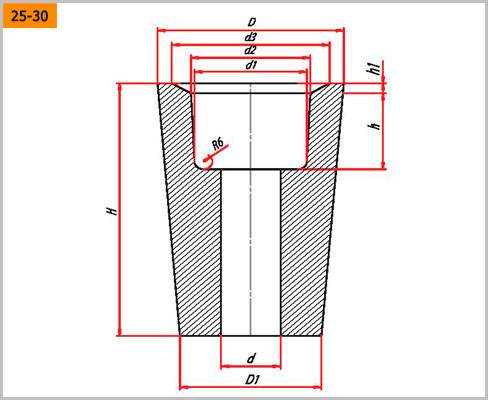

Form and dimensions

Stopper tube

| Number of bricks | Groups of brick | Dimensions, mm | In combination with stopper | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| H | h | h1 | D | D1 | D2 | d | d1 | d2 | |||

| 1 |

fire-clay, mullite-cilica, mullite, mullite-corundum |

300 | 10 | 13 | 100 | 67 | 63 | 40 | 72 | 67 | 9 |

| 2 | 300 | 14 | 17 | 125 | 81 | 75 | 48 | 86 | 79 | 10 | |

| 3 | 300 | 18 | 21 | 140 | 94 | 88 | 54 | 100 | 93 | 11 | |

| 4 | 300 | 18 | 21 | 160 | 106 | 100 | 60 | 111 | 104 | 12 | |

| 5 | 300 | 23 | 26 | 180 | 125 | 115 | 64 | 129 | 119 | 13 | |

| 6 | 300 | 23 | 34 | 180 | 125 | 115 | 64 | 129 | 115 | 13 | |

| 7 | 270 | 23 | 26 | 200 | 125 | 115 | 64 | 129 | 119 | 14 | |

| 8 | 270 | 23 | 34 | 200 | 125 | 115 | 64 | 129 | 115 | 14 | |

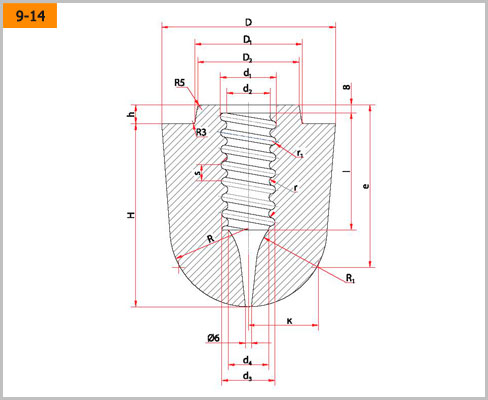

Stopper

| Number of brick | Dimensions, mm | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H | h | D | D1 | D2 | d1 | d2 | d3 | d4 | l | S | r | r1 | R | R1 | e | k | |

| 9 | 125 | 10 | 100 | 67 | 63 | 34 | 24 | 32 | 22 | 72 | 12 | 2.8 | 2.6 | 47.5 | 27 | 97 | 31 |

| 10 | 140 | 14 | 125 | 81 | 75 | 40 | 30 | 38 | 28 | 91 | 12 | 2.8 | 2.6 | 57.5 | 45 | 126 | 51 |

| 11 | 160 | 18 | 140 | 94 | 88 | 48 | 36 | 46 | 34 | 100 | 16 | 3.7 | 3.6 | 65.7 | 54 | 140 | 60 |

| 12 | 180 | 18 | 160 | 106 | 100 | 55 | 43 | 52 | 40 | 115 | 16 | 3.7 | 3.6 | 77.5 | 62 | 160 | 69 |

| 13 | 200 | 23 | 180 | 125 | 115 | 55 | 43 | 52 | 40 | 120 | 16 | 3.7 | 3.6 | 77.5 | 62 | 166 | 69 |

| 14 | 200 | 23 | 200 | 125 | 115 | 55 | 43 | 52 | 40 | 120 | 16 | 3.7 | 3.6 | 77.5 | 62 | 166 | 69 |

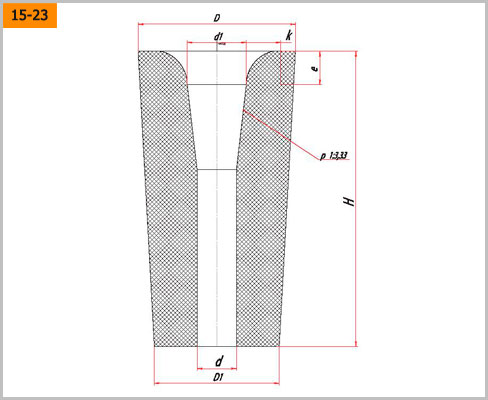

Nozzles

| Number of brick | Groups of brick | Dimensions, mm | In combination with stopper № | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| H | D | D1 | d | d1 | r | e | k | |||

| 15 | fire-clay | 140 | 140 | 112 |

24 |

|

35 | 34 | 60 | 9 |

| 26 | ||||||||||

| 28 | ||||||||||

| 30 | ||||||||||

| 32 | 50 | |||||||||

| 35 | ||||||||||

| 40 | ||||||||||

| 45 | ||||||||||

| 50 | 52 | |||||||||

| 16 | fire-clay | 240 | 160 | 120 | 20 | 65 | 35 | 34 | 67 | 11 |

| 22 | ||||||||||

| 24 | ||||||||||

| 26 | ||||||||||

| 28 | ||||||||||

| 30 | ||||||||||

| 35 | ||||||||||

| 40 | ||||||||||

| 45 | ||||||||||

| 50 | ||||||||||

| 55 | ||||||||||

| 60 | ||||||||||

| 70 | 72 | |||||||||

| 17 | fire-clay | 300 | 160 | 127 | 26 | 60 | 35 | 34 | 65 | 10, 11 |

| 30 | ||||||||||

| 35 | ||||||||||

| 40 | ||||||||||

| 45 | ||||||||||

| 50 | ||||||||||

| 55 | ||||||||||

| 60 | 62 | |||||||||

| 70 | 52 | |||||||||

| 18 | fire-clay | 360 | 160 | 120 | 30 | 65 | 40 | 37 | 72 | 11 |

| 35 | ||||||||||

| 40 | ||||||||||

| 45 | ||||||||||

| 50 | ||||||||||

| 55 | ||||||||||

| 60 | 72 | |||||||||

| 19 | fire-clay | 140 | 140 | 112 | 30 | 58 | 35 | 34 | 64 | 10 |

| 35 | ||||||||||

| 40 | ||||||||||

| 45 | ||||||||||

| 50 | ||||||||||

| 60 | 62 | |||||||||

| 20 | fire-clay | 300 | 160 | 127 | 30 | 68 | 35 | 34 | 69 | 10, 11 |

| 35 | ||||||||||

| 40 | ||||||||||

| 45 | ||||||||||

| 50 | ||||||||||

| 55 | ||||||||||

| 60 | ||||||||||

| 65 | ||||||||||

| 70 | 72 | |||||||||

| 21 | fire-clay | 360 | 160 | 120 | 30 | 68 | 55 | 51 | 88 | 12, 13, 14 |

| 35 | ||||||||||

| 40 | ||||||||||

| 45 | ||||||||||

| 50 | ||||||||||

| 55 | ||||||||||

| 60 | ||||||||||

| 65 | ||||||||||

| 70 | 52 | |||||||||

| 22 | fire-clay | 240 | 180 | 140 | 30 | 71 | 50 | 46 | 85 | 11 |

| 35 | ||||||||||

| 40 | ||||||||||

| 45 | ||||||||||

| 50 | ||||||||||

| 55 | ||||||||||

| 60 | ||||||||||

| 65 | ||||||||||

| 70 | 72 | |||||||||

| 23 | fire-clay | 370 | 210 | 146 | 30 | 67 | 90 | 86 | 120 | 12, 13, 14 |

| 35 | ||||||||||

| 40 | ||||||||||

| 45 | ||||||||||

| 50 | ||||||||||

| 55 | ||||||||||

| 60 | ||||||||||

| 70 | 82 | 65 | 64 | 105 | ||||||

| 80 | ||||||||||

| 90 | 102 | 54 | 54 | 105 | ||||||

| 100 | ||||||||||

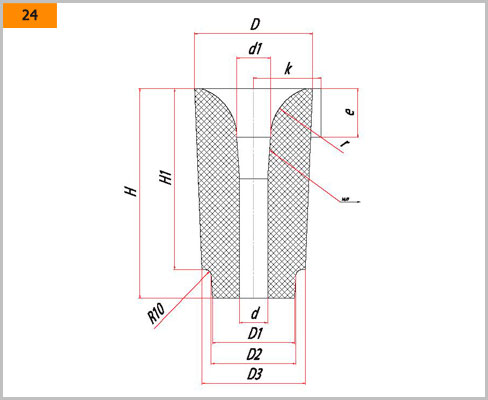

| Number of brick | Groups of brick | Dimensions, mm | In combination with stopper | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H | H1 | D | D1 | D2 | D3 | d | d1 | r | e | k | |||

| 24 | fire-clay | 370 | 320 | 210 | 146 | 152 | 180 | 30 | 67 | 90 | 86 | 120 | 12, 13, 14 |

| 35 | |||||||||||||

| 40 | |||||||||||||

| 45 | |||||||||||||

| 50 | |||||||||||||

| 55 | |||||||||||||

| 60 | |||||||||||||

| 70 | 82 | 65 | 4 | 105 | |||||||||

| 80 | |||||||||||||

| 90 | 102 | 54 | 54 | 105 | |||||||||

| 100 | |||||||||||||

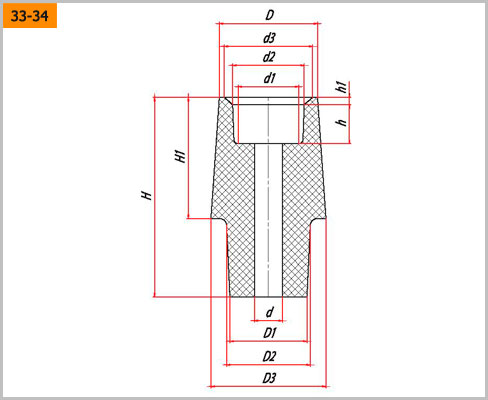

| Number of brick | Groups of brick | Dimensions, mm | In combination | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H | H1 | h | h1 | D | D1 | D2 | D3 | d | d1 | d2 | d3 | with insert № | with stopper № | ||

|

33 34 |

fire-clay |

280 360 |

170 250 |

65 |

8 | 140 | 110 | 120 |

164 175 |

30 | 98 | 102 | 126 | 10, 11 |

36 35 |

| 35 | |||||||||||||||

| 40 | |||||||||||||||

| 45 | |||||||||||||||

| 50 | |||||||||||||||

| 55 | |||||||||||||||

| 60 | |||||||||||||||

| Number of brick | Groups of brick | Dimensions, mm | In combination | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H | h | h1 | D | D1 | d | d1 | d2 | d3 | with insert № | with stopper № | ||

| 25 |

fire-clay |

200 | 60 | 8 | 125 | 95 |

30 35 40 |

75 | 80 | 106 | 35 | 9 |

| 26 | fire-clay | 140 | 60 | 8 | 140 | 112 |

30 35 40 |

75 | 80 | 106 | 35 | 9 |

|

27 28 |

fire-clay |

240 300 |

65 | 12 | 160 |

120 127 |

25 30 35 40 45 50 55 60 |

98 | 102 | 140 | 36 | 10, 11 |

|

29 30 |

fire-clay |

360 240 |

65 |

12 |

160 180 |

120 140 |

30 35 40 45 50 55 60 |

98 | 102 | 140 | 36 | 10, 11 |

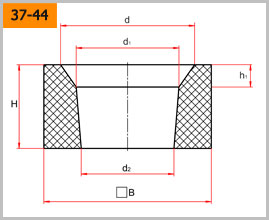

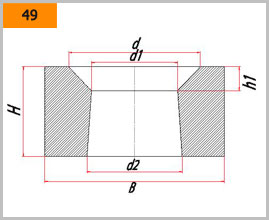

Well block

| Number of brick | Groups of brick | Dimensions, mm | In combination with nozzles № | |||||

|---|---|---|---|---|---|---|---|---|

| B | H | h1 | d | d1 | d2 | |||

| 37 |

fire-clay |

250 | 100 | 30 | 190 | 129 | 119 | 25 |

| 38 | 250 | 120 | 30 | 190 | 144 | 126 | 15, 19, 26 | |

| 39 | 250 | 120 | 30 | 225 | 184 | 169 | 22, 30 | |

| 40 | 300 | 150 | 40 | 240 | 184 | 166 | 22, 30 | |

| 41 | 300 | 150 | 40 | 240 | 164 | 146 | 16, 27 | |

| 42 | 300 | 150 | 40 | 240 | 164 | 152 | 17, 18, 20, 21, 28, 29 | |

| 43 | 360 | 150 | 60 | 300 | 215 | 200 | 23 | |

| 44 | 360 | 150 | 60 | 300 | 215 | 206 | 24 | |

| 49 | 300 | 150 | 40 | 220 | 144 | 159 | 33, 34 | |