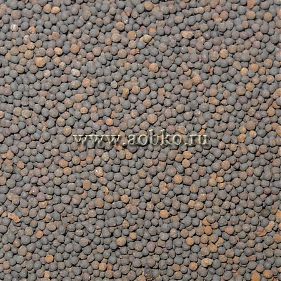

Aluminosilicate proppant

BORPROP | ALUMINOSILICATE PROPPANT

Aluminosilicate proppant is applicable for well sites of different depth and pressure, has high strength characteristics that allow making the best use of this proppant at pressures up to 10 000 psi (680 atm).

Bauxite base, homogeneity of structure, uniform crystallization of material, compact grain compact microstructure, absence of macrostructural defects allow Borprop proppant providing high operating characteristics of well yield in long-run period. At present JSC "Borovichi Refractories Plant" produces the following fraction assortment: 10/14,12/18,16/20,16/30,20/40,30/50,40/70

Technical characteristics

|

Physical-mechanical characteristics

|

10/14'

|

12/18'

|

16/20'

|

16/30'

|

20/40'

|

30/50'

| 40/70' |

|---|---|---|---|---|---|---|---|

|

Bulk weight, g/ccm

|

1.70 | 1.73 | 1.74 | 1.73 | 1.72 | 1.69 | 1.80 |

|

Specific Gravity, g/ccm

|

3.04 | 3.10 | 3.14 | 3.19 | 3.18 | 3.13 | 3.23 |

|

Sphericity

|

0.9 | 0.9 | 0.9 | 0.9 | 0.8 | 0.9 | 0.9 |

|

Roundness

|

0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.9 | 0.8 |

| Mean Size, mm | 1.648 | 1.162 | 1.041 | 0.798 | 0.620 | 0.497 | 0.339 |

|

Acid solubility HCI + HF, %

|

5.7

|

5.6 | 5.7 | 5.7 | 5.9 | 5.8 | 4.9 |

| Turbidity, FTU | 18 | 60 | 29 | 83 | 99 | 70 | 68 |

|

Crush Resistance (share of ruinous granules), %

|

|||||||

|

At 7500psi

|

15.7

|

7.9 | 6.4 | 3.4 | 2.0 | 0.9 | 0.5 |

|

At 10 000psi

|

22.0

|

11.8 | 9.1 | 6.2 | 4.6 | 2.4 | 1.3 |

|

At 12 500psi

|

29.8 | 14.3 | 12.4 | 7.9 | 6.3 | 3.0 | 1.8 |

|

At 15 000psi

|

40.5 | 20.5 | 16.4 | 10.8 | 10.0 | 4.9 | 2.3 |

CONDUCTIVITY, MD / FT

|

Pressure, psi

|

2000'

|

4000'

|

6000'

|

8000'

|

10000'

| 12000' |

|---|---|---|---|---|---|---|

|

10/14'

|

65 805 | 27 304 | 14 355 | 6 512 | 2 405 | 1 308 |

|

12/18'

|

25 642 | 17 962 | 10 125 | 5 552 | 2 910 | 2 038 |

|

16/20'

|

21 345 | 13 667 | 9 314 | 5 049 | 2 943 | 1 670 |

|

16/30'

|

14 771 | 8 944 | 6 286 | 3 890 | 2 251 | 1 293 |

|

20/40'

|

7 044 | 4 563 | 3 417 | 2 324 | 1 520 | 961 |

|

30/50'

|

4 257 | 3 555 | 3 000 | 2 040 | 1 300 | 933 |

| 40/70' | 1 622 | 1 420 | 1 266 | 1 022 | 828 | 662 |

PERMEABILITY, DARCY

|

Pressure, psi

|

2000'

|

4000'

|

6000'

|

8000'

|

10000'

| 12000' |

|---|---|---|---|---|---|---|

|

10/14'

|

3 500 | 1 588 | 877 | 421 | 163 | 92.9 |

|

12/18'

|

1 408 | 1 025 | 603 | 345 | 188 | 137 |

|

16/20'

|

1 246 | 835 | 589 | 332 | 202 | 119 |

|

16/30'

|

862 | 544 | 395 | 253 | 151 | 90.2 |

|

20/40'

|

414 | 277 | 214 | 151 | 102 | 66.9 |

|

30/50'

|

250 | 215 | 185 | 130 | 85.0 | 62.8 |

| 40/70' | 99.3 | 88.9 | 80.6 | 66.1 | 54.5 | 44.3 |